Short-time welding is used for stud diameters of 3-10mm. It has the particular advantage that, compared to the other drawn arc processes, thinner sheets can also be welded (1/8 x D) due to the short, shallow fusion. The welding time is 5 to 100 ms at a current of up to 1900 A.

It can be easily automated and can also be combined with gas-shielded welding.

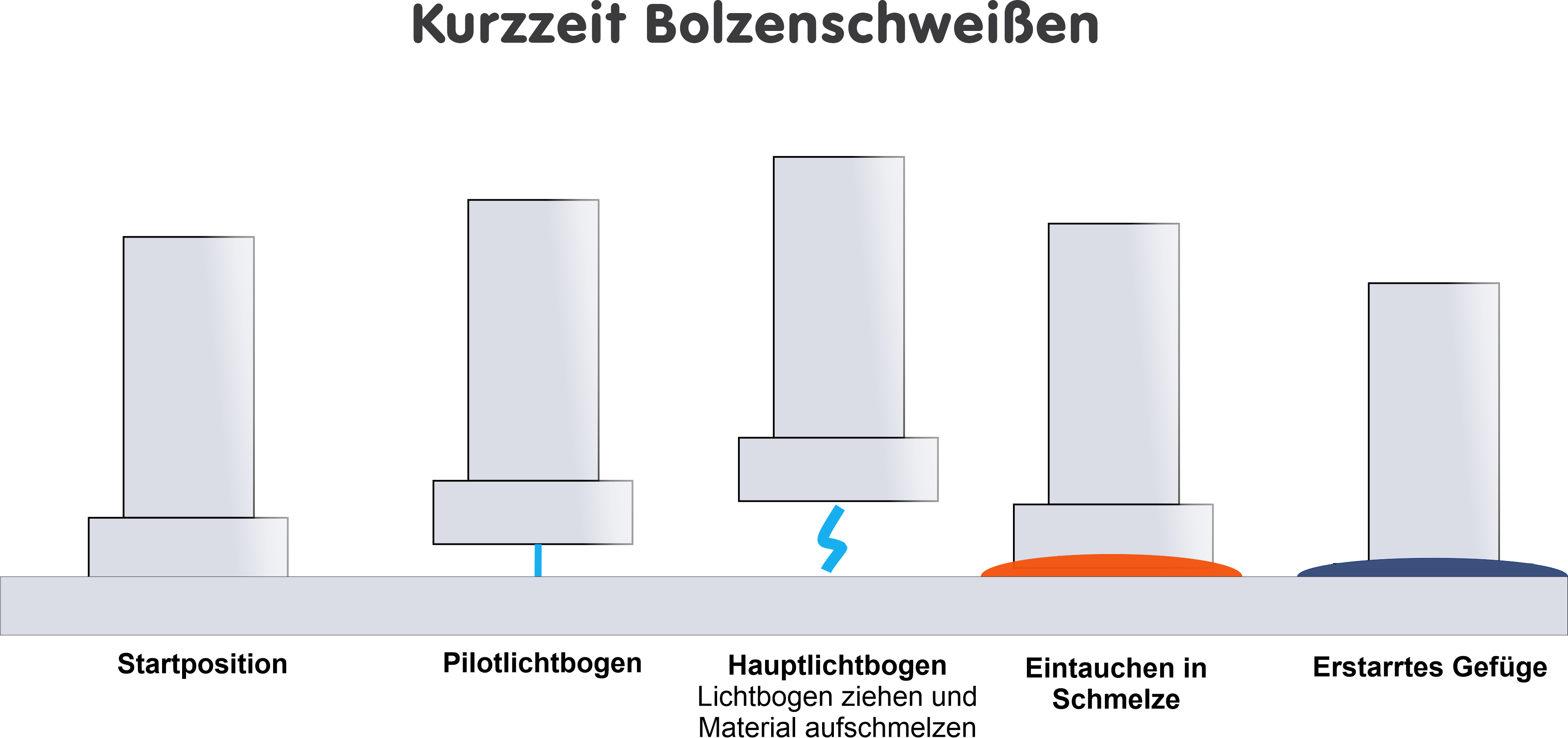

prozess sequenzes:

At the beginning, the stud is placed on the workpiece and lifted off. A pilot arc is first generated with a low electric current. After a short " holding time ", the main arc, which melts the materials, is initiated.

All in all the stud is lifted from the workpiece and then plunged into the molten metal of the workpiece during the set welding time. The welding time is considerably shorter in the case of short cycle procedure than in the case of ceramic ring welding. Immediately after the device has been lifted off. The finished weld result is directly available.

At the end, there is the permanently welded stud. In the graphic, you can find a schematic representation of the welding process.